CeraCFM Auto Ladle 2.5 kg

3200.0 आईएनआर

उत्पाद विवरण:

- प्रॉडक्ट टाइप

- सिरेमिक टाइप

- मटेरियल

- Click to view more

X

मूल्य और मात्रा

- 1

- Insulated, Rugged Build

- 220/415V, 50 Hz

- Automatic

- Mechanical Arm Operated

- Foundry, Metal Casting

- Molten Metal Pouring

- 1600°C

- 2.5 kg

- Programmable Logic Controller (PLC)

उत्पाद की विशेषताएं

- Insulated, Rugged Build

- 220/415V, 50 Hz

- Automatic

- Mechanical Arm Operated

- Foundry, Metal Casting

- Molten Metal Pouring

- 1600°C

- 2.5 kg

- Programmable Logic Controller (PLC)

व्यापार सूचना

- ,

- प्रति सप्ताह

- हफ़्ता

- Yes

- ,

- ,

उत्पाद विवरण

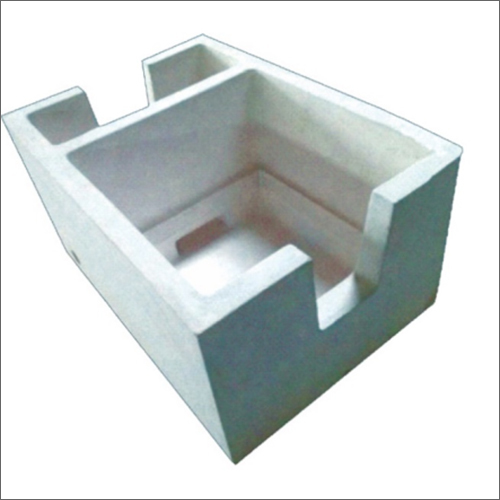

CeraTherm offers CeraCFM(Ceramic Covered Fabric Material), a PATENT Published MOLTEN METAL TRANPORTING DEVICE in different types and forms.

Steel Body or Structure of Ladle is covered with protecting layers of Ceramic composite material with the help of fiberglass fabric wrapped. This helps to get the better performance and better life because it is a combination of Steel and Ceramic Material.

The material used is highly insulating and low thermal conductivity which helps to maintain the temperature of molten metal while transferring or pouring.

The whole structure or main body is made of steel and covered with ceramic and fiberglass fabric, so its build the better strength in the device compare to other available devices made of ceramic. It helps to prevent the chances of accident due to mechanical damage.

Hand Pouring Ladle available for GDC, HPDC, Sand Casting.

Standard Designs available for HPDC Auto Pouring.

Customized Designs available for GDC Auto Pouring & Saucer.

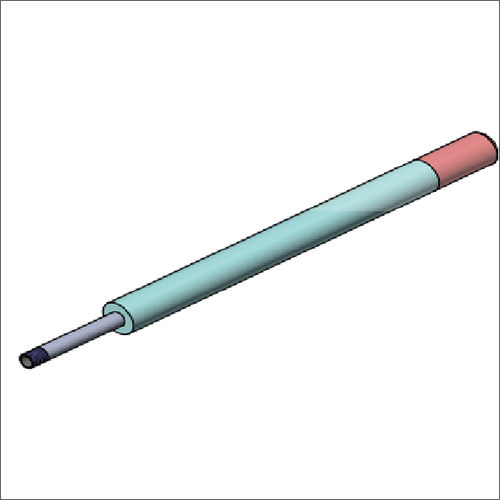

Thermocouple Protection Tubes for Thermocouples.

Feeder Tubes for LPDC Application.

Degassing Tubes for Degassing Application.

Precision Pouring with Automation

The CeraCFM Auto Ladle streamlines molten metal handling by automating the pouring process. Controlled via PLC, it guarantees consistent results in metal casting, significantly reducing human error while improving throughput. Its mechanical arm offers smooth, accurate motion, enabling operators to maintain quality standards and maximize efficiency.

Optimal Safety and Rugged Durability

Engineered from high-performance ceramic and alloy steel, the insulated construction of the ladle ensures operational safety at temperatures up to 1600C. The rugged design minimizes maintenance needs, providing long-lasting performance even in demanding foundry applications.

FAQ's of CeraCFM Auto Ladle 2.5 kg:

Q: How does the CeraCFM Auto Ladle operate in a foundry environment?

A: The CeraCFM Auto Ladle utilizes a mechanical arm, operated automatically through a programmable logic controller (PLC), ensuring precise and repeatable molten metal pouring during casting processes in foundries.Q: What is the maximum temperature the CeraCFM Auto Ladle can handle?

A: This ladle is designed to operate safely at temperatures up to 1600C, making it suitable for handling various molten metals in metal casting applications.Q: When should I use the CeraCFM Auto Ladle in my casting process?

A: The Auto Ladle is ideal for use during the pouring phase of metal casting, especially when consistent dosing and safety are required for handling molten metals in high-temperature environments.Q: Where is the CeraCFM Auto Ladle typically utilized?

A: The ladle is primarily employed in foundries and metal casting facilities where accurate and automated molten metal pouring is essential for production efficiency and safety.Q: What steps are involved in the automated pouring process with this ladle?

A: Operators initiate the system via PLC controls, after which the mechanical arm picks up and tilts the ladle, delivering the exact amount of molten metal into molds as programmed, ensuring uniform casting results.Q: How does using this automated ladle benefit production?

A: Automation improves precision, reduces labor requirements, enhances safety, and increases throughput, leading to more consistent castings and a safer working environment.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें